Full scale test of AE testing for broken cable

Brief:QingCheng AE Institute was invited to conduct an experiment thet detecting the broken wire of a bridge cable with RAEM1 acoutic emission monitoring system, and we successfully detected all the broken wire signal without any signal missing.

Project Overview

On July 1, 2022, Qingcheng AE Institute (Guangzhou) Co., Ltd. was invited by a research institute to conduct a full-size cable loading and wire breaking experiment on the cable (hanger) produced by a cable factory and the actual bridge hanger with 1:1 production. The two-week full scale test of acoustic emission detection for broken wires of bridge cables was successfully completed with remarkable results. Experimental data show that RAEM1 can be unattended and remote automatic monitoring of broken wires to ensure that no single broken wire is missed, and can automatically push broken wires and the rate of broken wires to mobile phones and mailboxes.

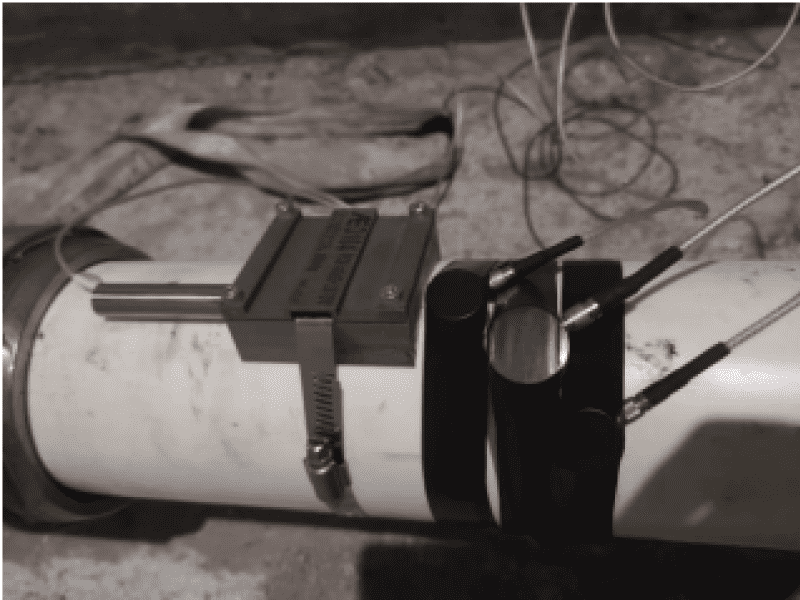

Fig.1 Bridge special sensor installation

Fig.2 RAEM1 Internet of Things Acoustic Emission Collector

Fig.3 RAEM1 Principle of Iot Acoustic Emission System

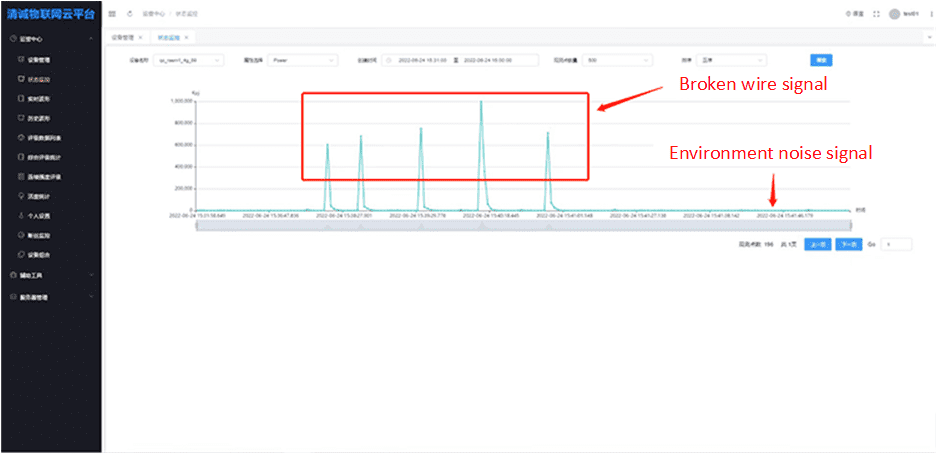

Fig.4 Qingcheng Internet of Things platform to check the broken wire data

|

|

NO. |

Event Time |

Energy |

Counts |

Total wire broken amount |

Wire broken rate |

Alarm precision rate |

|

1 |

1 |

2020-07-01 10:19:28.002 |

11986 |

175 |

8 |

6.01% |

100% |

|

2 |

2020-07-01 10:19:56.264 |

17502 |

209 |

||||

|

3 |

2020-07-01 10:20:23.310 |

15702 |

193 |

||||

|

4 |

2020-07-01 10:20:30.589 |

11501 |

187 |

||||

|

5 |

2020-07-01 10:20:35.842 |

22272 |

211 |

||||

|

6 |

2020-07-01 10:20:54.539 |

13748 |

199 |

||||

|

7 |

2020-07-01 10:20:03.479 |

13455 |

192 |

||||

|

8 |

2020-07-01 10:20:14.212 |

15446 |

187 |

||||

|

2 |

1 |

2020-07-01 10:31:16.511 |

14311 |

183 |

17 |

12.78% |

100% |

|

2 |

2020-07-01 10:31:36.324 |

26892 |

213 |

||||

|

3 |

2020-07-01 10:31:48.274 |

10186 |

190 |

||||

|

4 |

2020-07-01 10:31:53.430 |

17032 |

209 |

||||

|

5 |

2020-07-01 10:31:56.521 |

13325 |

187 |

||||

|

6 |

2020-07-01 10:32:00.881 |

22072 |

204 |

||||

|

7 |

2020-07-01 10:32:08.468 |

14983 |

195 |

||||

|

8 |

2020-07-01 10:32:10.541 |

29296 |

224 |

||||

|

9 |

2020-07-01 10:32:27.976 |

18101 |

205 |

||||

|

3 |

1 |

2020-07-01 10:47:46.621 |

15926 |

182 |

26 |

19.55% |

100% |

|

2 |

2020-07-01 10:48:05.754 |

14360 |

196 |

||||

|

3 |

2020-07-01 10:48:07.765 |

15337 |

206 |

||||

|

4 |

2020-07-01 10:48:12.710 |

14609 |

192 |

||||

|

5 |

2020-07-01 10:48:16.878 |

20007 |

247 |

||||

|

6 |

2020-07-01 10:48:18.385 |

14429 |

230 |

||||

|

7 |

2020-07-01 10:48:57.937 |

12278 |

176 |

||||

|

8 |

2020-07-01 10:49:11.875 |

15527 |

204 |

||||

|

9 |

2020-07-01 10:49:19.881 |

24730 |

226 |

-

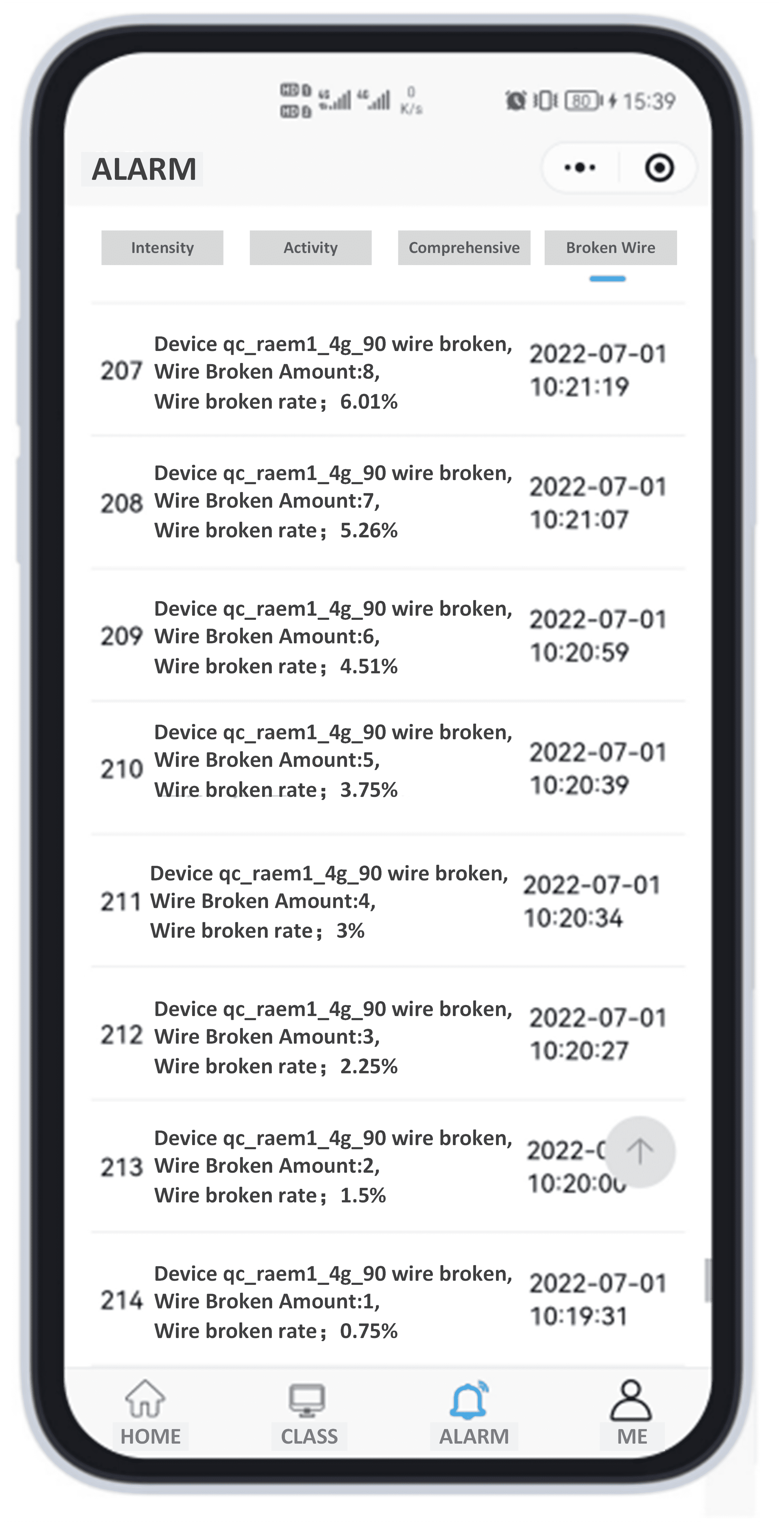

Fig.5 Some experimental results

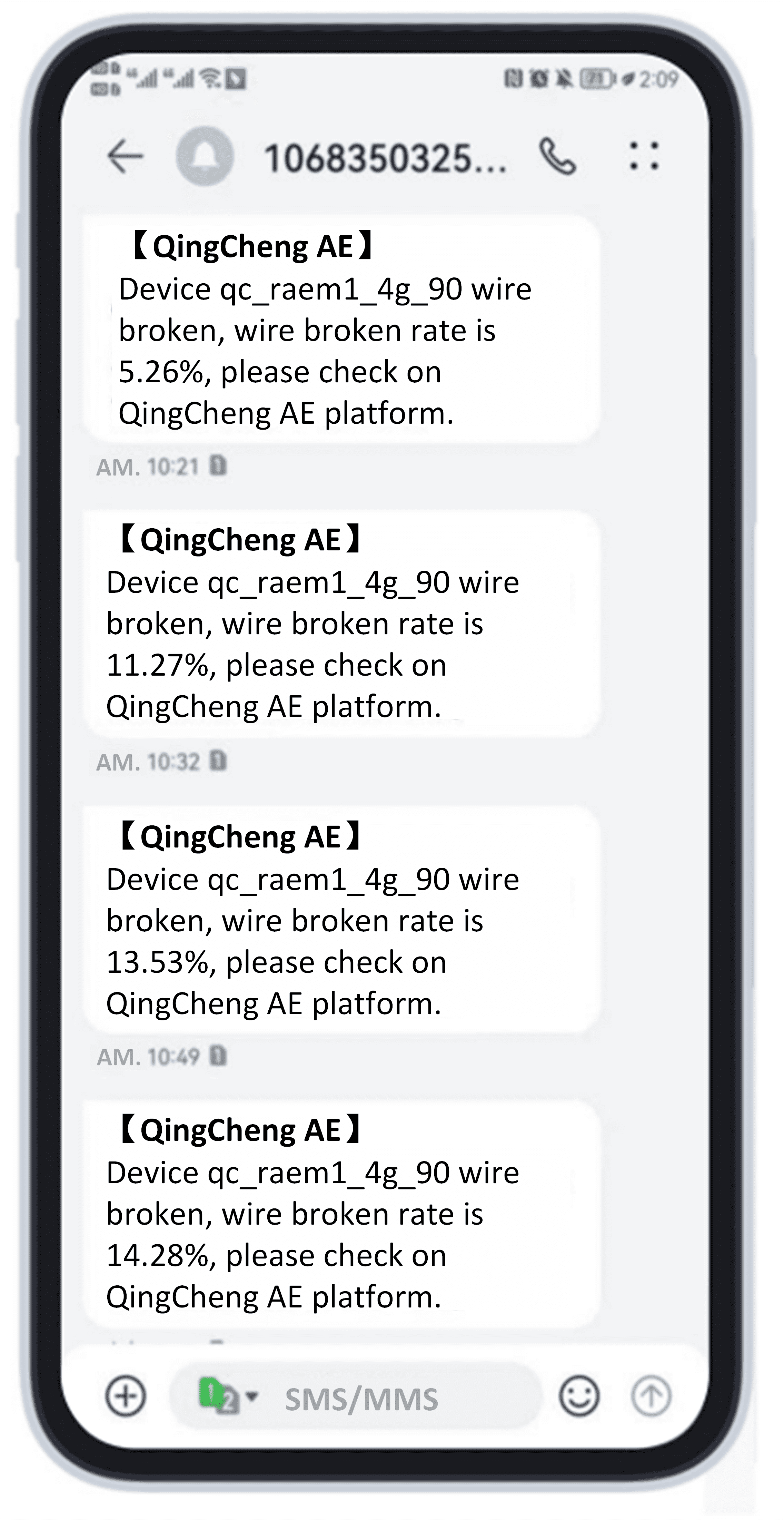

Fig.6 Wire breaking and wire breaking rate alarm push

Conclusion:

The acoustic emission signal of broken wire has high amplitude, high energy, high ring count, high RMS and obvious characteristics, which can be distinguished from most noise signals. The data and results of this experiment show that acoustic emission testing can effectively detect the phenomenon of broken wires. The data and results of this experimental study also prove that the RAEM1 iot acoustic emission monitoring system can accurately and effectively monitor the phenomenon of wire breakage, and the 100% accuracy of the experimental data of wire breakage has no missing report. RAEM1 can be unattended remote automatic monitoring of broken wire, so as not to miss a single broken wire phenomenon, and can automatically push broken wire and broken wire rate to mobile phone and email.

The experimental data show that the energy and RMS value of the broken wire signal at the anchor head are much larger than that at the casing. The data show that a single sensor installed at the unjacketed anchor head position can effectively detect wire breakage throughout the cable.